A resource blog for Industrial Designers that posts video tutorials and other useful things from across the web.

Friday, 23 July 2021

Wednesday, 21 July 2021

Design for Disassembly: This Old Idea is the Wave of the Future by Sarah Templin

The quick and intuitive disassembly of my French press means that I can easy clean it and replace or recycle its parts as needed.

The quick and intuitive disassembly of my French press means that I can easy clean it and replace or recycle its parts as needed.

The stats feel tired at this point: the EPA tells us that over 10 million tons of furniture are taken to US landfills each year, and more than 2 thousand tons of major appliances will be tossed onto the heap in 2021 alone. As product designers, this can lead us straight to an existential fever dream, imagining Victor Papanek whispering in our ear: "There are professions more harmful than industrial design, but only a few."

The reality is that consumption-based capitalism isn't going anywhere. But we as designers and business leaders have the opportunity and the agency to devise ways to implement healthier making and sourcing methods by rethinking our approaches to design.

How can our products' life spans be prolonged? How can our designs encourage repair? How can we insist on our work's participation in a circular economy? I give you, with as much bravado as I may, our solution: Design for Disassembly (DfD).

DfD is the wave of the future, but it is also an old idea. This article will kick off a 3-part series to address the importance of designing for disassembly, acknowledge its traditional roots, and review how designers are implementing it in industries not typically associated with DfD.

A Refresher: Remind Me Again What Design for Disassembly is?

Design for Disassembly (DfD) is the straightforward design method and philosophy that ensures that all elements of a product can be disassembled for repair and for "end of life." This allows for and encourages repairs, with the result that a product's life cycle is prolonged; and it allows for a product to be taken apart at the end of its life so that each component can be reclaimed as a technical nutrient (i.e. recycled) or biological nutrient (i.e. composted). Among other shifts in thinking and making, this means minimizing materials, using simple mechanical fasteners instead of adhesives, clearly labeling components with their material type, and ensuring components can be disassembled with everyday tools.

When I broke the glass vessel of my French press this weekend, I ordered a replacement vessel instead of purchasing an entirely new coffee maker. This was only possible because my French press was designed so that it could be easily disassembled. On the other hand, my electric kettle has started to leak. There are no small screws for me to open it – in fact, it's mostly glued together. This means that when I finally cave and admit that this kettle is broken, I have no way to repair it and no way to recycle its parts. In contrast to the French press, the product was not designed for disassembly. My only option is to throw it out, and to buy a new one.

As mentioned, DfD is not a new concept. (My favorite past Core 77 article espousing its virtues is Alex Denier's Essential Guide to Design for Disassembly, which still feels like a very handy guide even 10 years later.) DfD is, however, a concept that has been painfully slow to catch on despite its obvious benefits, with plenty of companies backsliding in the opposite direction towards glued, bonded, and overshot parts – if not planned obsolescence.

Green It Like You Mean It

Unlike the nebulous goal of designing a "sustainable" product, designing a product for disassembly is a more concrete, quantifiable approach to ecologically sound making and to consumption. Off the bat, it throws the curtain back on corporate greenwashing. If a company says they're sustainable, how is the average customer to know what's really going on behind the scenes? If a company commits to DfD, however, then we can concretely understand their barometer for sustainable production.

Here in the U.S., sustainability goals often hinge on material choices, a common example being the choice of materials from recycled content (or materials that can be recycled). Designing with recyclable materials is great but, at best, it kicks the can down the road, placing the burden onto future generations or users. At worst, it gambles that the customer cares, that they can recognize or are paying attention to a wide variety of materials in the first place, and that they live in a municipality that recycles at all.

Designing with recyclable (or recycled) material, simply put, is the bare minimum that we designers can do. On the other hand, upping our commitment to DfD encourages longevity through a culture of repair. It sets the stage for building a stronger relationship with consumers through a more enduring product-user engagement, and establishes an advantageous association with "premium" and quality design – that is, designs made to last.

Europe Loves to Set the Pace

Outside of the U.S. it can be more common to see a system-based approach to reducing waste and increasing a product's longevity. The Right to Repair Law, for example, was passed in Europe last Spring. It requires that electronics like washing machines, televisions, and hair dryers sold in the E.U. must be designed to allow for easy repair for at least 10 years after the product comes to market. This legislation intentionally prolongs a product's durability and repairability while minimizing e-waste. (Additional upcoming legislation in the E.U. focuses on smartphones and laptops, which account for a large portion of global e-waste.) The most straightforward way to fulfill these new requirements is to make sure that DfD is front and center in universal design processes – and, to precede that, in universal design conversations and education, too.

The U.S. is often just a few years behind the E.U. when it comes to sustainability regulations, so this is a likely harbinger of what requirements will soon be instituted more globally. From there, public opinion and consumer behavior soon follow. So to proactively design products for disassembly means that our work as designers can become more universally compliant, while also satisfying more world-wide cultural expectations from the consumer side.

Standardizing DfD is an important step in establishing a more circular economy. It allows us to reclaim product components for future use and reduces costs of goods sold by eliminating materials redundancy; positions us to use safer and more healthful materials that in turn affect conditions in both factory and in end-user settings; and it removes the onus from consumers to figure out how to responsibly dispose of their products. It's a win-win-win. And these "wins" are

necessary for the future of design, and the future of our planet.

from Core77 https://ift.tt/2W66gx7

via IFTTT

Tuesday, 20 July 2021

Student Recycles Paper and Cardboard Into a Wood-Like Material, Using 3D-Printed Molds by Rain Noe

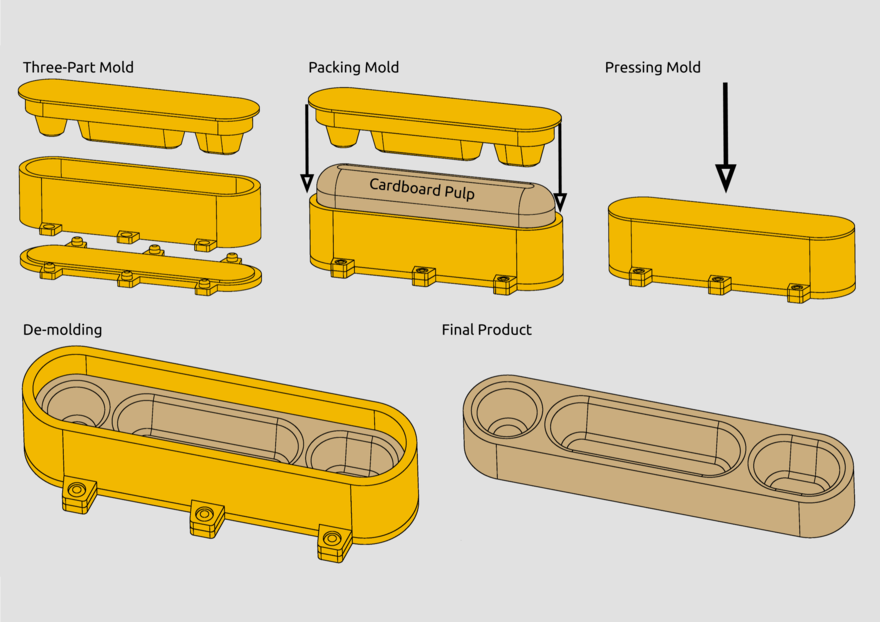

If Aidan Leitch was an Industrial Design student, I think any ID professor would give him an A-plus for this project. (Leitch, a self-described "shape enthusiast," is actually a Mechanical Engineering student at USC.) Leitch has intensively studied the material of paper and conducted a series of experiments to see how he could re-shape it, using mostly household technologies. After pulping it in a blender with water, then combining it with a DIY binding agent made from rice, Leitch figured out how to press it into a wood-like material using 3D-printed molds:

He then sought to make useful objects out of the stuff:

Along the way, Leitch learned that the material takes to detailed texture well—the striations from the 3D-printed molds showed up sharply—and can be sanded and drilled through with relatively clean holes. He also conducted some torture-testing to see what would make it break, landing on water as the enemy of this material.

Even more impressive than the end product is Leitch's process, which you can see below. Hands-on and curiosity-driven, Leitch does his homework, understands that experimentation requires relentless iterating, and after successfully realizing his creation, literally takes a hammer and a torch to it to see what would make it fail. He understands the capabilities and limitations of the material thoroughly. He also cites his direct inspiration for the project, which was the similar technique he witnessed while interning at 3D Brooklyn, a design and prototyping firm.

from Core77 https://ift.tt/3xPm0Co

via IFTTT

Friday, 16 July 2021

Industrial Design Student's Solar Car was Actually Prototyped by Rain Noe

Few industrial design students can expect, while still students, to design an entire car—both the interior and exterior—that will actually be prototyped. But that's exactly the opportunity pursued by Daniel Rauch, who was studying ID at Germany's Folkwang University of the Arts back in 2017. In conjunction with the Bochum University of Applied Sciences, German industrial engineering conglomerate Thyssenkrupp was developing the third generation of their blue.cruiser, a solar-powered car, and tapped Rauch for the project. Thyssenkrupp and the university then actually built a functioning prototype of Rauch's design.

"The design of the thyssenkrupp blue.cruiser combines the silhouette of a classic coupe with a clear and modern design language."

"As a student at the Folkwang University of the Arts in Essen, Daniel Rauch designed the entire vehicle (exterior, interior, color and trim) on his own. He accompanied the process from the first sketches and concepts, through simulation CAD models and production data, to the final design and ensuring implementation down to the last detail."

"More efficient and practical for everyday use than ever before, the new four-seater features a spacious and modern interior. Innovative lightweight steel structures characterize the development of the body: the lattice frame with roll cage, the specially developed steel rims and the rear seat made of the sandwich material LITECOR represent the increased use of steel and have the advantage of making the car particularly light - without compromising on safety. In addition, as in any other sports coupe, there are special features such as distance warning, central locking, info display, heated seats and electrically adaptable suspension for maximum driving comfort."

I do wonder what happened to the car, but the website for it doesn't mention its current condition nor whereabouts.

Today Rauch is a fully minted industrial designer with his own firm. You can check out his work here.

from Core77 https://ift.tt/3B9wtdS

via IFTTT

Tuesday, 13 July 2021

Industrial Design Duo Creates a Fast-Access Camera Strap for Cyclists by Rain Noe

Bay-Area-based Jonathan Ota calls himself "a hybrid interaction and industrial designer working at the intersection of the physical and digital worlds." While his day job is as a UX designer, on nights and weekends he's been working on a physical object designed for those with the dual hobbies of cycling and photography.

Ota teamed up with fellow industrial designer Jessica Chan, who specializes in soft goods and runs Tunitas Carryall, the bicycle bag company she founded. Together they created the Makers in Motion Camera Strap. The three-point strap is designed to keep the camera stable and out of the way when you're pedaling, but provides quick access to take a spontaneous snap when you're ready.

The quick-release attachment point is magnetic:

The duo launched a Kickstarter campaign for the strap, which was 100% funded in less than a day. Congratulations to Ota and Chan!

from Core77 https://ift.tt/36AeKy8

via IFTTT

Friday, 2 July 2021

In the Midst of Radical Workplace Change, This Project Offers Innovative Collaboration Tools for Remote Teams by Core77 Design Awards

Many say the emergence of COVID-19 simply accelerated cultural trends that already existed, but you could argue the most surprising change occurred in the workplace when many companies shifted from offices to fully remote. And as countries and cities begin to open up, there's further proof there's little chance we'll ever revert back to a 100% office-bound work culture.

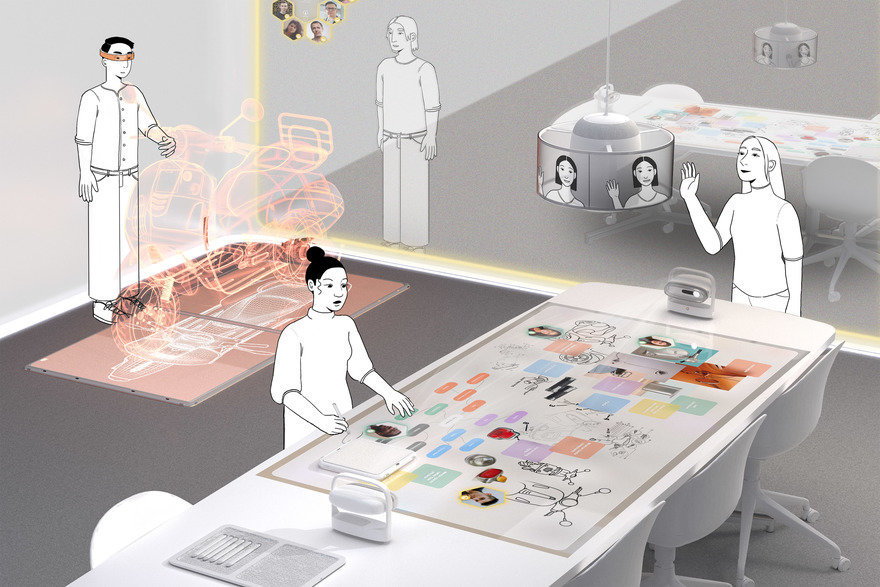

Throughout the past year, many designers familiar with the importance of working together as teams were hard at work dreaming up solutions for how to collaborate remotely without sacrificing quality of experience. This challenge prompted a partnership between Western Washington University's Industrial Design Program and Seattle-based product design firm Anvil Studios to create a number of solutions for this recent professional conundrum. The result was "Ampersand," a collection of four collaboration tools for remote teams.

The Ampersand collection concept was inspired by a prompt from Anvil Studios and designed entirely remotely by a group of college seniors influenced by our own experiences of collaborating while in isolation. Each product works in tandem with other products within the system, making for a symbiotic user flow that makes remote work as seamless as possible.

First in the Ampersand collection is the Virtual Work Hub called "&", an app that shares worker activity within one centralized location. In addition to being an information hub displaying what coworkers are up to, the app also features a digital whiteboard interface that pairs with the next product in their collection, the Ampersand Collaborative Projector.

This Collaborative Projector product concept is a portable projection device allowing workers to create smart surfaces on demand and provide input through gestures or via a digital writing device. The device is meant to work in tandem with a stylus designed by the team, which enables active brainstorming and concept development between teammates on the same screen in remote locations.

The next product, the Communication Lamp, allows coworkers to co-collaborate on their feet while seeing each other in real time. As described by Western Washington students involved in the project, "The Ampersand Lamp simulates face-to-face conversation between in-house and remote teammates, through multi-directional cameras and a flexible, transparent screen. The screen features a conference mode for displaying the 'speaker view' during video calls, as well as a diffuse screensaver. When not in use, the camera retracts into the Lamp, ensuring user privacy and comfort."

Finally, a haptic tile designed by the team helps coworkers visualize product iterations in a three-dimensional field by allowing colleagues to quickly send and review 3D models. Tiles are optimized for use with augmented reality headsets, which allow stakeholders and team members to view files in a 3D plane. Orthographic views are displayed on the screens of each tile to assist in surface modeling. Inside each Tile is an array of small ultrasonic transducers which function together to produce detailed haptic bodies.

So while it's inevitable the environments in which we work may be rapidly changing, what is clear is the need for collaboration and communication with others will always remain relevant—Ampersand helps to address this problem in a way that feels evergreen and lasting, creating genuine interactions even when teammates don't have the opportunity to work within the same literal space.

Ampersand is a Student Notable in the Interaction category of the 2021 Core77 Design Awards. You can check out all of the 2021 winners now on the Core77 Design Awards website.

from Core77 https://ift.tt/3xaCNQd

via IFTTT

Great Industrial Design Student Work: The Attaché Folding Stool by Rain Noe

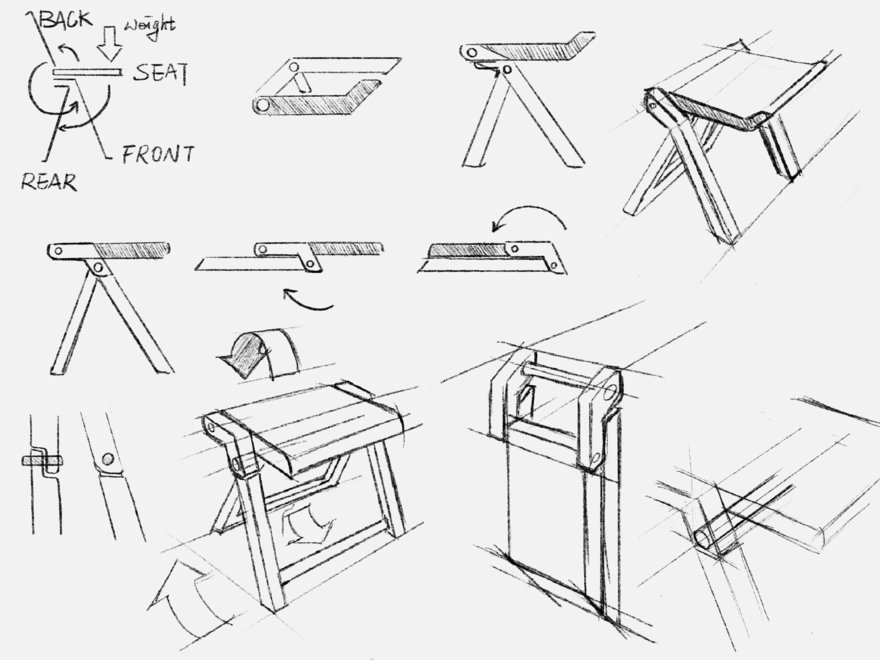

"There are some problems with folding furniture," observed mechanical engineer Chi-Hao Chiang, who left his native Taiwan to pursu...

-

Pendant lighting is free-floating and static, whereas adjustable lighting is typically attached to a jointed arm. Berlin-based industrial de...

-

The New School's Parsons School of Design is located in New York City, where you may or may not want to go after the pandemic is over. ...